WHAT IS AN INDUSTRIAL WATER CHILLER? PRACTICAL APPLICATIONS IN SOUTHERN VIETNAM

An industrial water chiller is a system designed to generate and maintain a stable chilled water supply for cooling molds, machinery, or entire production lines. Circulating chilled water enables precise temperature control, reduces product defects, and ensures stable operational performance.

In Southern Vietnam, industrial water chillers are widely used across multiple industries. In the plastics industry, chillers are essential for cooling injection molding and extrusion molds, ensuring consistent cycle times. The food and beverage sector relies on chillers to control processing and preservation temperatures. Cold storage, cold logistics, pharmaceuticals, and chemical industries all require accurate and continuous chilled water supply. Additionally, industrial water chillers for plastics and precision engineering play a crucial role in protecting equipment and extending machinery lifespan.

SOUTHERN VIETNAM CLIMATE CHARACTERISTICS AND TECHNICAL REQUIREMENTS FOR CHILLER SELECTION

Southern Vietnam features high ambient temperatures, high humidity, and fluctuating thermal loads across production shifts. Many factories operate 24/7, especially in plastics, food processing, and cold storage industries. These conditions place strict demands on industrial water chiller systems.

First, the chiller must deliver efficient heat rejection under high ambient temperatures without performance degradation during peak hot seasons. Second, the system must operate reliably over long periods, minimizing unplanned downtime. In addition, energy efficiency has become a top priority as manufacturers seek to reduce long-term operating costs.

Beyond performance, industrial water chiller design must match factory layouts and existing water systems. Selecting the correct configuration from the outset helps prevent overcapacity, undercapacity, and unnecessary energy waste.

COMMON TYPES OF INDUSTRIAL WATER CHILLERS

Classification by Compressor Technology

Industrial water chillers are commonly categorized by compressor technology. Mono chillers feature a simple configuration and are suitable for factories with stable thermal loads and consistent cooling demand. They are widely used in basic systems due to ease of operation and maintenance.

Inverter chillers can modulate capacity according to actual load, significantly reducing power consumption during partial-load operation. For factories with variable production schedules, inverter chillers offer clear economic benefits.

More advanced DC inverter chillers utilize sophisticated control technology to achieve higher efficiency and optimal energy savings, making them ideal for facilities operating continuously.

Classification by Cooling Method

Based on cooling methods, industrial water chillers are divided into air-cooled and water-cooled systems. Air-cooled chillers are easy to install and do not require cooling towers, making them suitable for many factories in Southern Vietnam. Water-cooled chillers offer higher efficiency and are typically used in large-capacity projects or applications with strict cooling requirements.

In practice, manufacturers in Southern Vietnam increasingly prefer inverter and DC inverter chillers to optimize long-term energy costs.

KEY CRITERIA FOR SELECTING THE RIGHT INDUSTRIAL WATER CHILLER

To select a suitable industrial water chiller in Southern Vietnam, manufacturers must accurately determine cooling capacity and actual thermal load. Incorrect calculations can result in wasted investment or insufficient capacity during operation.

Choosing the right technology—Mono, Inverter, or DC Inverter—should be based on production characteristics. Initial investment cost should be evaluated alongside long-term operating expenses, particularly electricity and maintenance. Most importantly, companies should work with experienced suppliers who understand Southern Vietnam’s climate, operating conditions, and factory-specific requirements to ensure optimal system performance.

WHITE COOL INDUSTRIAL WATER CHILLER SOLUTIONS FOR SOUTHERN VIETNAM

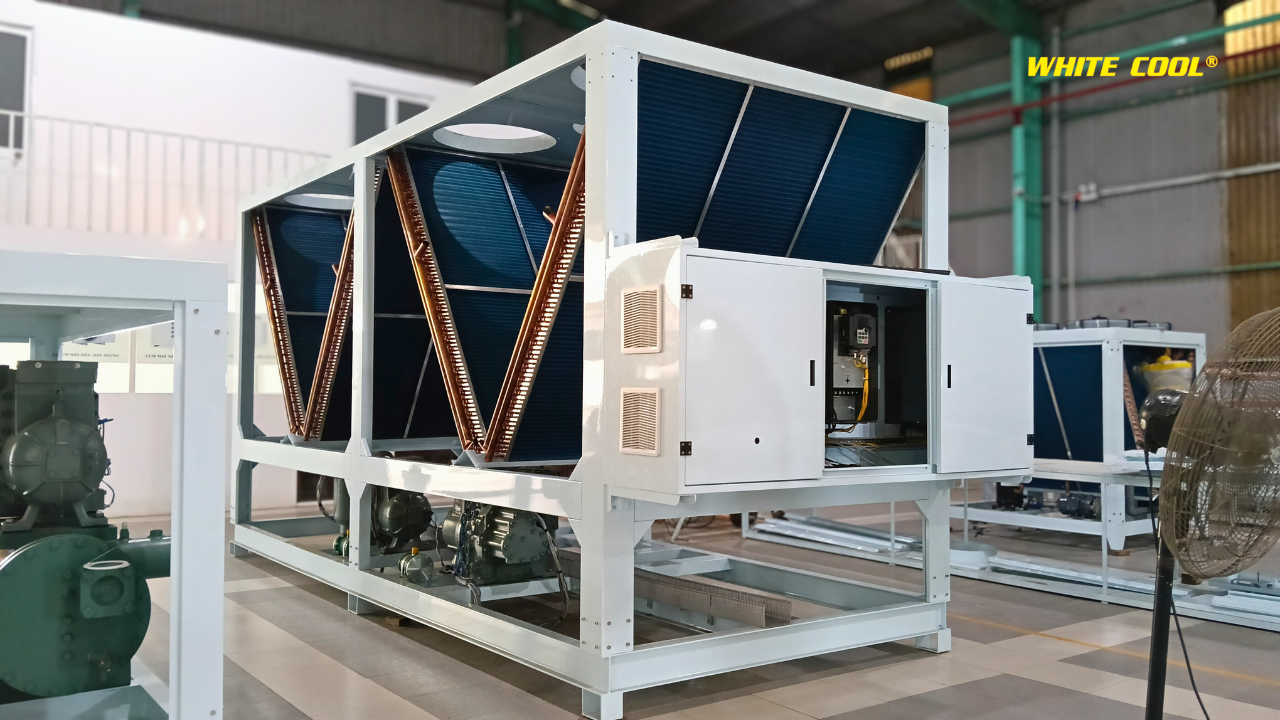

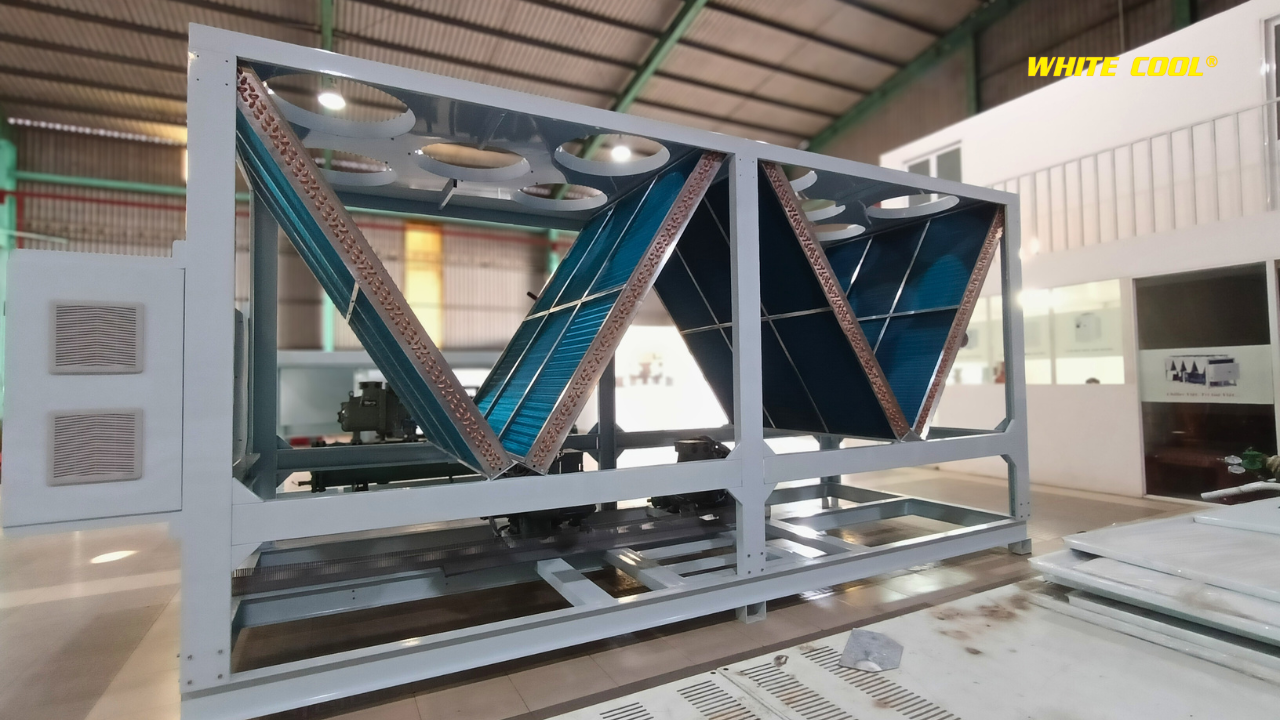

White Cool is a specialized manufacturer and supplier of industrial water chillers for B2B customers. White Cool systems are engineered and manufactured to match real operating conditions in Vietnam, especially in Southern Vietnam.

White Cool’s product range includes Mono, Inverter, and DC Inverter chillers, available in both air-cooled and water-cooled configurations. Mono chillers provide stable performance and easy maintenance for constant-load systems. Inverter chillers reduce energy consumption and adapt efficiently to variable loads. DC inverter chillers are optimized for 24/7 factory operations, delivering high efficiency and superior energy savings.

White Cool’s strength lies not only in its products but also in its total solution approach. Customers receive accurate load assessment, application-specific configuration, customized system design, and fast technical support throughout Southern Vietnam.

CONCLUSION

Industrial water chillers are a critical investment that directly impacts production efficiency and operating costs. Choosing the right technology and a reliable supplier in Southern Vietnam ensures stable operation, long service life, and long-term energy savings.

Contact White Cool today for system assessment, professional consultation, and a tailored industrial water chiller solution with a detailed quotation for your factory.